It seems as if the Holladay Distillery just came out of nowhere with releases that are getting a lot of attention lately. The history of Ben Holladay dates to 1856 when Ben and his brother David distilled their first batch of bourbon under the Blue Springs Distillery brand. You can read the history of Ben Holladay and the distillery here. Through the years, the distillery’s name changed five times and only changed ownership three more times. In 1942, the distillery was renamed when it was sold to the McCormick Distilling Company and kept its name when purchased by Midwest Grain Products (MGP) in 1950. In 1993, the McCormick Distilling Company was acquired by Virgin Islands Rum Industries, Ltd., owned by Edward A. Pechar and the late Michael S. Griesser. Under this new ownership, McCormick Distilling continued to produce neutral spirits and, over the next two decades, more than doubled its product line. Their website says, in 2015, “The McCormick Distillery underwent a $10 million dollar renovation of the original stillhouse and began distilling bourbon on-site for the first time in 30 years, resurrecting the Holladay Distillery name in honor of the original founders”.

Besides meeting the federal standards for bourbon, a 2019 law says that Missouri bourbon must also be mashed, fermented, distilled, aged, and bottled in the state, aged in oak barrels manufactured in Missouri. On January 1, 2020, an addition was added that required a Missouri bourbon to be made with corn exclusively grown in the state.

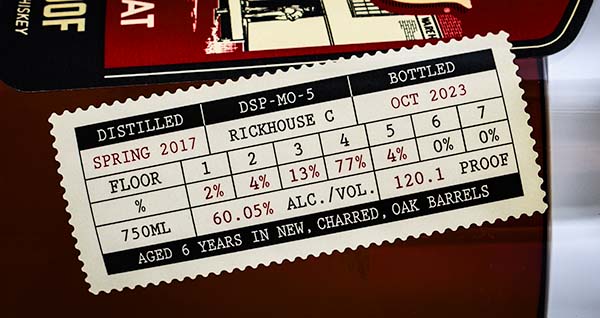

Holladay Distillery is using an 18” diameter Vendome Copper column still at a distillation proof of 120. Two different-sized grain cookers are used; one is a large high-temperature cooker used for corn, and the other is a smaller lower-temperature cooker used for all the other grains. The soft red wheat mash is cooked at a lower temperature than the rye mash. A sour mash is produced with a 72-hour fermentation time fed by a limestone spring water source that dates to the original 1800s distillery. Independent Stave Company is used for their cooperage with a char level #3 on the staves, and a barrel distillate entry proof of 118, filling about 12 barrels a day, 7 days a week. All their bourbon is non-chill filtered. Holladay uses two non-temperature-controlled rickhouses for their flagship line. Rickhouse B was built in the 1930s and holds 10,000 barrels, and rickhouse C was built in the 1950s and holds 12,000 barrels. Each rickhouse has 7 floors with a 30-degree variance between the first and top levels. The temperatures in Weston climb to 100 degrees in the summer while dropping below zero in the winter.

The age statement on Holladay’s flagship line is six years, which is impressive they waited that long for their first release, never having sourced their whiskey. However, there is a plan in action for older-aged releases down the road. On the 10th of every month, Holladay holds back 10 barrels to be aged for 10 years in rickhouse B. The Ben Holladay rye bourbon mash bill was created from research based on historical distillery records, but a wheated bourbon was never produced at this distillery before. The idea to create the Soft Red Wheat bourbon came from Holladay’s president, Mick Harris, simply because Mick is a big fan of Maker’s Mark and wanted to create a wheated bourbon. The Soft Red Wheat bourbon was first released on March 25, 2003. On the Holladay Distillery website is a Distiller’s Journal, where you can read production notes from Master Distiller Kyle Merklein, and listen to what Kyle has to say in the Holladay Happy Hour podcasts. For the October 2023 batch I’m reviewing, Kyle says, “I had no desire to do another single floor release like what we did in August. Rather, the plan was to again keep a very balanced bourbon that had a nice mix throughout the rickhouse. The one interesting challenge with this batch was that I was trying to allocate all of the remaining barrels for the Soft Red Wheat Spring 2017 distillation season. This was still another large batch for us – a total of 181 barrels were dumped to produce both the BiB and Rickhouse with a barrel loss of 30.0% during aging. The Rickhouse Proof version is 120.1 proof for this bottling. A total of 17 different ricks were used from floors 1-5 with a weighted (floor) average of 3.77. Because of the various ricks used, a total of 32 distilling days were used in the batch from the Spring 2017 distilling season”. With that, let’s get started!

Taken: Neat in a Glencairn glass, rested for about 15 minutes.

Distillery: Holladay Distillery in Weston, Missouri.

Proof: 120.1, non-chill filtered.

Age: 6 years, October 2023 release.

Mash bill: 73% Corn/15% Wheat/12% Malted Barley.

Price: $74.99.

Appearance: Golden caramel.

Nose

First up are sweet oak flavors of pralines, butterscotch, and toffee, with vanilla icing and pie crust. There’s a generous amount of cherries, ripe peaches, and baked apples with herbal notes of rosemary, nutmeg, and a hint of green tea. There’s also a significant floral note in the mix with toasted hazelnuts. I love the soft wheat pie crust “texture” mixed with the sweet oak and fruit-forward flavors of this profile. The balance of flavors is fantastic, with very little proof heat.

Palate

The palate transfers to the nose with sweet oak flavors of toffee, butterscotch, and pralines. The sip continues with fruit flavors of peaches, cherries, and baked apples, with vanilla beans, sage, nutmeg, floral, and toasted oak. A good balance of allspice enters the sip, covering the whole palate. It’s an incredibly delicious pour with some proof heat, but it’s very controlled and easy to drink.

Finish

Allspice lingers over the palate, along with toffee, butterscotch, vanilla, cherries, peaches, and a floral note that comes back around. Oak and soft tobacco tannins linger with allspice to the end of a very long and delicious finish.

Conclusion

I can see what all the hype is about. I love a great wheated bourbon, and Soft Red Wheat Rickhouse proof checks all the boxes. It has a wheated bourbon soft pie crust quality that helps brings out the fruit flavors, with plenty of sweet oak and a well-balanced balanced amount of spice that pulls it all together. I’m also impressed with Holladay Distillery’s transparency and nod to the past with the bottle design and the front-label illustration based on a 1940s photo. I was surprised to see the screw top. I’m okay with a screw top, but I’m used to seeing a cork for bottles in this price range. I was told that McCormick has always used a screw top for their products. They believe that it keeps a tighter seal and stays true to the distillery’s heritage, which used screw tops dating back to the 1930s. There’s not much else I can say about Holladay Soft Red Wheat Rickhouse Proof other than that I highly recommend it if you love wheated bourbons. I’m looking forward to their future releases.

Rating: 7.8/10.

1 | Disgusting | So bad I poured it out.

2 | Poor | I wouldn’t consume by choice.

3 | Bad | Multiple flaws.

4 | Sub-par | Not bad, but better exists.

5 | Good | Good, just fine.

6 | Very Good | A cut above.

7 | Great | Well above average.

8 | Excellent | Really quite exceptional.

9 | Incredible | An all time favorite.

10 | Perfect | Perfect.